Torsion Springs

A torsion spring is a type of mechanical spring that works by exerting torque or twisting force when it is twisted along its axis. The spring is made of wire that is wound in a spiral shape, with the ends of the wire attached to a stationary point on one end and a rotating point on the other end. When the rotating point is turned, the spring stores energy by twisting, and when the rotating force is released, the spring unwinds and releases the stored energy. Although the name implies otherwise, torsion springs are subjected to bending stress rather than torsional stress. They can store and release angular energy or statically hold a mechanism in place by deflecting the legs about the body centerline axis.

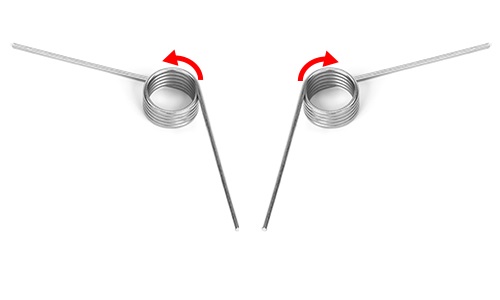

A torsion spring is normally close wound but can have a pitch to reduce friction between the coils. Torsion springs resist twisting or rotationally applied force. Depending on the application, a torsion spring can be designed to work in a clockwise or counterclockwise rotation, which will determine the direction of the wind.

Torsion Spring Applications

Torsion springs are commonly used in a variety of applications, such as in door hinges, garage doors, levers, and various types of machinery. They are also used in toys, clocks, and other consumer products where a rotating force is required. Sizes range from miniature, used in electronic devices, to large torsion springs used in chair control units. Torsion springs can be made of various materials, including steel, stainless steel, and other alloys, depending on the specific application requirements. They are valued for their ability to provide high torque and for their durability and long lifespan.

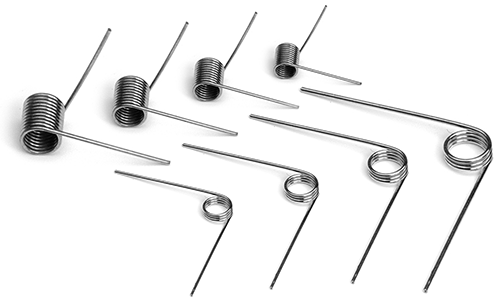

Torsion Spring Configurations

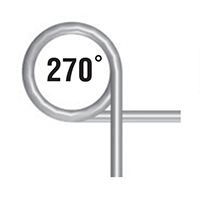

There are many options for torsion spring leg configuration so the torsion spring can be attached in different ways. Leg specifications to consider for a torsion spring include leg angle, leg length, and leg style. Springs that are straight or parallel on the same side are considered to have a 0º leg angle and the increasing angle is in the unwinding direction. Common torsion spring designs include straight torsion spring, straight offset torsion spring, hinged torsion spring, short hook end, and hook end designs. Torsion spring ends can be designed with custom bends, twists, hooked or looped end to suit your project needs. Lee Spring stock torsion springs are offered in a choice of 90 degree, 120 degree, 180 degree, 210 degree, 270 degree, 300 degree and 360 degree free leg position with straight legs. Custom double torsion springs consist of one set of coils coiled right hand and one set of coils coiled left hand. These coils are connected, usually with an unwound section between the winds and work in parallel. The sections are designed separately with the total torque being the sum of the two.

What is unique about Torsion Springs?

One of the unique features of a torsion spring is that it can store and release energy through twisting motion, as opposed to the more common compression and extension motion of other types of springs. This twisting motion allows the torsion spring to generate high torque or rotational force, making it well-suited for applications where a rotating force is required, such as in door hinges, garage doors, and various types of machinery.

Another unique aspect of torsion springs is that their properties can be adjusted by varying their design parameters, such as wire diameter, outer diameter, and number of coils. This makes them highly customizable and versatile, allowing them to be tailored to meet the specific requirements of different applications. Additionally, torsion springs are known for their high durability and long lifespan, due to their ability to withstand repeated twisting and untwisting without experiencing fatigue failure. This makes them a reliable and cost-effective choice for many industrial and consumer applications.

Stock Torsion Springs

Lee Spring’s stock torsion springs have been carefully designed to represent the most commonly used specifications in both inch and metric sizes. Stock torsion springs are offered in a wide range of options and configurations and are available for immediate delivery from our large inventory. Select from thousands of design options, leg angles, and leg lengths, plus left-hand and right-hand wound springs. Stock torsion springs are offered in a variety of spring materials including music wire, stainless steel 302 and stainless steel 316. Lee Spring music wire springs include plating and stainless steel stock torsion springs, which are ideal for corrosion resistance, include passivation.

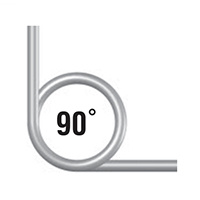

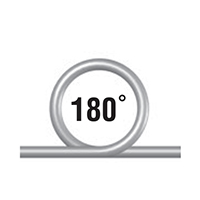

Stock Torsion Spring Free Angles

90° Degree Torsion Spring

120° Degree Torsion Spring

180° Degree Torsion Spring

210° Degree Torsion Spring

270° Degree Torsion Spring

300° Degree Torsion Spring

360° Degree Torsion Spring

Lee Spring offers free standard ground shipping on stock torsion spring orders, free plating, expert engineering assistance, live customer support service and much more. Lee Spring stock torsion springs are offered with legs of equal length oriented at varying unloaded angles.

Search Stock Torsion Springs

Custom Torsion Springs

Lee Spring can manufacture custom torsion springs to meet your exact specifications for all your projects. We offer experienced engineering support from design through production. Select from an extensive selection of material and finish options that will be ideal for your torsion spring design application. In addition, we can support your project with CAD assisted torsion spring design, governmental and industrial regulatory expertise, and prototypes through large production runs. Lee Spring offers advanced manufacturing capabilities and a wide variety of options for your torsion spring manufacturing needs such as; advance quality control systems, regulatory expertise including RoHS, REACH and DFARS, CAD assisted product design, in-house prototype production services and global supply chain network. Simply request a quote today or contact a Lee Spring Engineer for design assistance or to answer any questions to help start your custom spring project.

To learn more about the various spring materials and spring finishes commonly used for torsion springs:

Learn more about torsion spring materials

Learn more about torsion spring coatings and surface treatments

Learn more about what can cause a torsion spring to fail

Request a custom torsion spring quote

Torsion Spring Design Considerations

Torsion spring have a number of design elements to consider when working with a torsion spring design. The following is a list of key design considerations when working with torsion springs in your application:

- Torsion spring loads should be specified at a fixed angular position and not at a fixed deflection from the free position.

- Torque spring testing is not easy to perform. Torque measurements for torsion springs can be taken, they may be inconsistent.

- Torsion spring inner diameter reduction and potential binding should be considered in your application.

- For torsion spring applications that require minimum hysteresis (load loss) torsion springs should be designed with space between adjacent coils to reduce frictional losses.

- A torsion spring should always be loaded in a direction that causes its body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction that increases body diameter.

- Clearance must be maintained between the mandrel and the torsion spring at all times to prevent binding. The ideal mandrel size is equal to, or slightly less than, 90% of the inside diameter. when the spring is fully deflected (minimum diameter). Mandrels significantly smaller than 90% should be avoided to prevent buckling during large deflections.

- Most torsion springs are close wound; therefore, the torsion spring body length will increase when a spring is deflected in the direction that will reduce the coil diameter. In tight housing designs, this increase should be considered.

- Torsion spring direction of wind must always be specified for a torsion spring.

You can determine direction of wind of a torsion spring by simply holding it in your hand with your fingers placed around the outside of the body and your thumb pointing straight up. If the last coil ends in the same direction that your fingers are pointing, that is the hand (direction of wind) of the spring. The wind of the torsion spring can be right hand, left hand, or double torsion. Good design dictates that torsion springs should be used in the direction that winds the coil.

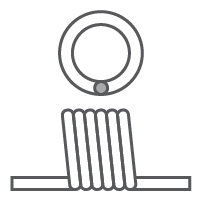

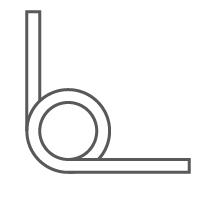

Common Torsion Spring Leg Configurations

Torsion springs can be designed and manufactured in wide range of torsion spring end and leg configurations. Special torsion spring leg configurations are available on request. When designing torsion spring ends, it is important to consider that bends, loaded to decrease their radius of curvature, have favorable residual stresses. They can operate at higher applied stress levels than bends that increase the radius by loading. Frequently, torsion spring performance is limited because the sharply bent ends have greater stress than the body.

Axial Torsion Spring Leg Configurations

0 Degree

90 Degree

180 Degree

315 Degree

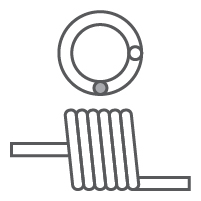

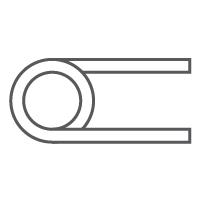

Tangential Torsion Spring Leg Configurations

0 Degree

90 Degree

180 Degree

315 Degree

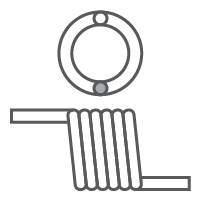

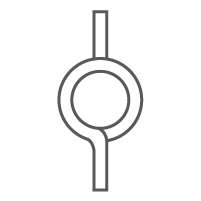

Radial Torsion Spring Leg Configurations

0 Degree

90 Degree

180 Degree

315 Degree

Radial Center Over Tangential Torsion Spring

0 Degree

90 Degree

180 Degree

315 Degree

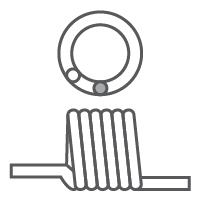

Double Torsion Springs

Special types of torsion springs include double torsion springs and springs having a space between the coils to minimize friction. Double torsion springs consist of one set of coils coiled right hand and one set of coils coiled left hand. These coils are connected, usually with an unwound section between the winds and work in parallel. The sections are designed separately with the total torque being sum of the two.

Torsion Spring Terminology

Active Coils: The number of coils in the spring that are compressed or extended when it is under load.

Angular Deflection: The angle of rotation as measured from the free position to the installed, intermediate or final positions.

Free Angle: The angle between the arms of a torsion spring when the spring is in the unloaded position.

Inner diameter: The inner diameter of the spring, which is the diameter of the circle that the wire makes when the spring is not under any load.

Leg Length: The length of the straight sections at each end of the spring, which are used to attach the spring to other components.

Mandrel: A rod or shaft over which a torsion spring operates.

Material Type: The type of material used to make the spring, which can affect its strength, durability, and other properties.

Maximum Deflection: The maximum amount that the spring can be twisted before it reaches its elastic limit and starts to deform permanently.

Outer Diameter: The outer diameter of the spring, which is the diameter of the circle that the wire makes when it is wound into a spiral.

Radius: The bend radius at which a load is applied to a leg. The radius is usually assumed to be equal to ½ the leg length.

Spring Rate: The amount of torque that the spring exerts for a given angle of twist, which is usually measured in units of torque per unit of angle (such as Nm/degree or lb-in/radian).

Torque: A twisting action in torsion springs which produces rotation, equal to the load multiplied by the distance from the load to the axis of the spring body.

Total Coils: The number of coils in the spring when it is under no load.

Wire Diameter: The diameter of the wire used to make the spring, which is typically specified in inches or millimeters.

Sign Up/Log In

Sign Up/Log In

.png)