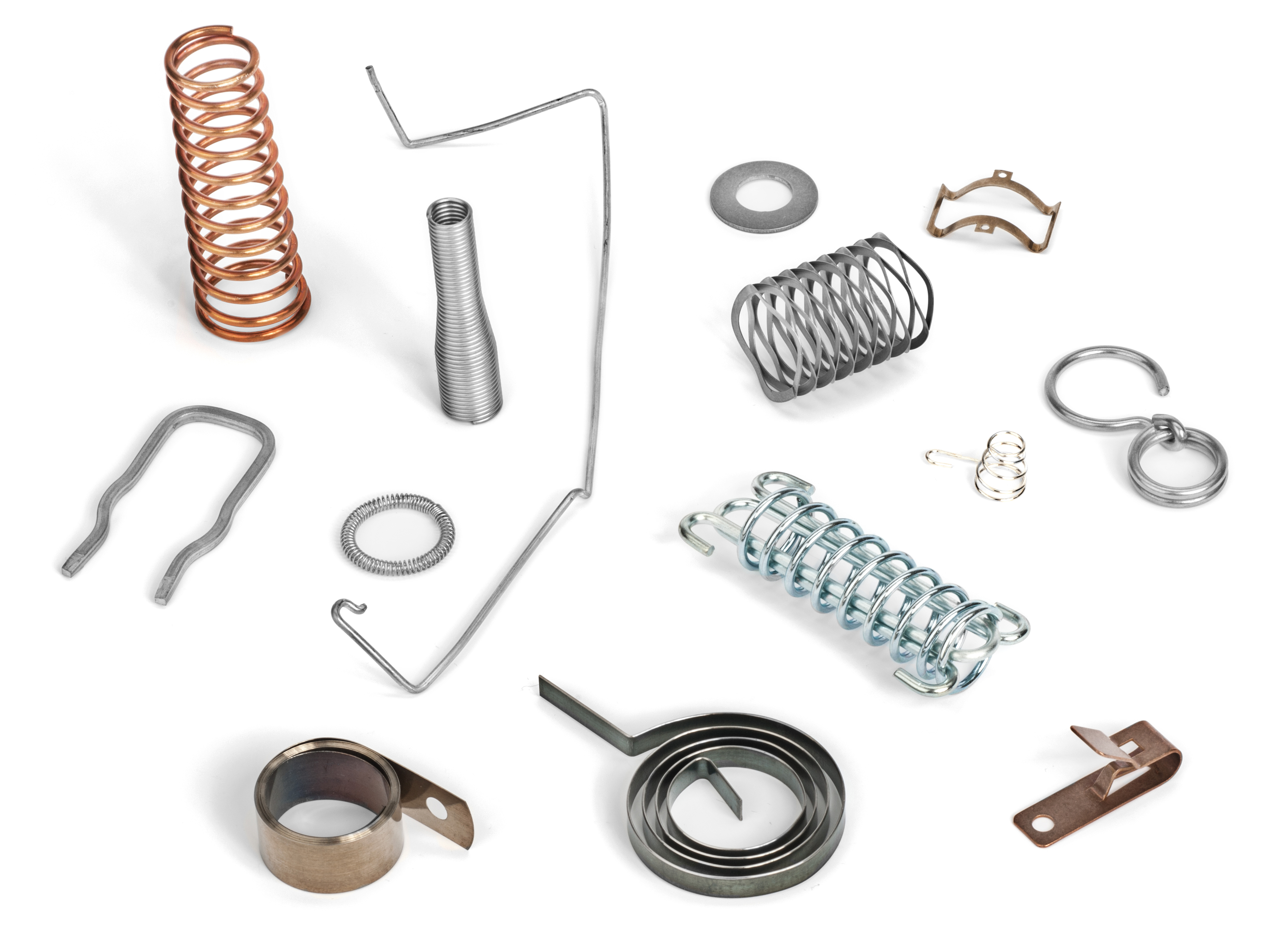

Spring Materials

Lee Spring offers both stock springs and springs made to specifications in many material options. Depending on the application, the right material can make all the difference in the performance of a spring. Common considerations with regards to material include operating temperature, corrosion resistance requirements and spring parameters needed. A Lee Spring Engineer is available to assist with material inquiries should you have questions regarding a specific application or material.

High Carbon Steels

Stainless Steels

Alloy Steels

Composite

Copper Alloys

Nickel Alloys

| Lee Spring Stock Series Materials | ||||||||

|---|---|---|---|---|---|---|---|---|

| Stock Spring Series | Music Wire | Stainless Steel | Elgiloy | Oil Tempered MB | Chrome Silicon | Beryllium Copper | Ultem | |

| Compression | LeeP Plastic Composite | X | ||||||

| Bantam Mini Series | X | |||||||

| Instrument Series | X | X | ||||||

| Lite Pressure Series | SS316 | |||||||

| Standard Series | X | X | ||||||

| Heavy Duty Series | X | X | X | |||||

| High Pressure Series | 17-7 PH | |||||||

| REDUX Wave Series | 17-7 PH | |||||||

| HEFTY Die Springs | X | X | ||||||

| DIN-Plus Series | X^ | X^ | ||||||

| Extension | X | X | ||||||

| Torsion Springs | X | X | ||||||

| Belleville Washers | 300 Series | |||||||

| Constant Force | 301 | |||||||

| Battery Springs | X | X | ||||||

| Continuous Length Extension | X | 302 | ||||||

| Spring Kits | X | X | ||||||

| Drawbar | X | |||||||

| MIL-SPEC Compression | X* | 302 DFARS | ||||||

| MIL-SPEC Extension | X* | 302 DFARS | ||||||

* Uncoated per ASTM A228 (or) Cadmium Plated Music Wire (or) Zinc plated Music Wire Available

X^ Similar grades as per EN 10270

Material Properties

High Carbon Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Oil Tempered MB |

ASTM A229 | C 0.55 - 0.85%, Mn 0.30 - 1.20% | 0.28 | Class I: 165 - 293, Class II: 191 - 324 | 30 | 11.5 | 250 °F | General purpose spring wire for average stress applications. Highly magnetic. Often used for larger wire sizes when Music Wire is not available. |

Hard Drawn MB |

ASTM A227 | C 0.45 - 0.85%, Mn 0.30 - 1.30% | 0.28 | Class I: 147 - 283, Class II: 171 - 324 | 30 | 11.5 | 250 °F | General purpose spring wire for low to average stress applications. Cold drawn to desired properties. Highly magnetic. |

Music Wire |

ASTM A228 | C 0.70 - 1.00%, Mn 0.20 - 0.70% | 0.28 | 230 - 399 | 30 | 11.5 | 250 °F | High quality spring wire that is cold drawn with good surface finish. Highly magnetic. Generally good fatigue life due to high tensile strength. |

Alloy Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Oil Tempered Chrome Vanadium |

ASTM A231 | C 0.48 - 0.53%, V 0.15 Min %, Mn 0.70 - 0.90%, Cr 0.80 - 1.10% | 0.28 | 190 - 300 | 30 | 11.5 | 425 °F | Alloy steel spring wire used for shock loads and moderately elevated temperatures. Highly magnetic. Available in Valve Spring quality in accordance with ASTM A232. |

Oil Tempered Chrome Silicon |

ASTM A401 | C 0.51 - 0.59%, Cr 0.60 - 0.80%, Si 1.20 - 1.60% | 0.28 | 224 - 300 | 30 | 11.5 | 475 °F | Alloy steel spring wire used for shock loads and moderately elevated temperatures. Highly magnetic. Available in Valve Spring quality in accordance with ASTM A877. |

Stainless Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Stainless Steel 17-7 PH |

AMS 5678 | Cr 16.0 - 18.0%, Ni 6.5 - 7.7%, Al 0.75 - 1.5% | 0.28 | Cond. CH900: 230 - 343 | 29.5 | 11 | 650 °F | Improved strength over 300 Series stainless steels with similar heat and corrosion resistance. Slightly magnetic. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Stainless Steel 316 |

ASTM A313 | Cr 16.5 - 18.0%, Ni 10.5 - 13.5%, Mo 2.0 - 2.5% | 0.29 | 125 - 245 | 28 | 10 | 550 °F | General heat resistant spring wire and better corrosion resistance than Type 302/204. Slightly magnetic. Often used in marine applications, resists chloride attack. |

Stainless Steel 302/304 |

ASTM A313 | Cr 17.0 - 20.0%, Ni 8.0 - 10.5% | 0.29 | 130 - 325 | 28 | 10 | 550 °F | General purpose corrosion and heat resistant spring wire. Slightly magnetic. Type 304 has less carbon than Type 302, however considered commercially equivalent for stock springs. |

Copper Alloys

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Monel K 500 |

QQ-N-286 | Ni 63.0 min%, Cu 27.0 - 33.0%, Al 2.3 - 3.1% | 0.31 | 160 - 200 | 26 | 9.5 | 550 °F | Similar corrosion and heat resistance to Monel 400 with better strength. Good for subzero and cryogenic applications. |

Monel 400 |

AMS 7233 | Ni 63.0 min%, Cu 28.0 - 34.0% | 0.32 | 145 - 180 | 26 | 9.5 | 450 °F | Nickel-copper alloy spring wire with good corrosion resistance at moderately elevated temperatures. Good mechanical properties for subzero temperature applications. Generally resistant to hydrofluoric, sulfuric, and hydrochloric acids. Typical for marine and chemical processing applications. |

Brass |

ASTM B134 | Cu 68.5 - 71.5%, Zn 28.5 - 31.5% | 0.31 | 120 min | 16 | 6 | 200 °F | Good combination of strength and ductility for cold working. Properties based on 70-30 Spring Brass (C26000) sub-type. Used in fresh water and seawater applications. |

Beryllium Copper |

ASTM B197 | Cu 98.0%, Be 1.8 - 2.0% | 0.30 | 160 - 230 | 18.5 | 7 | 400 °F | Non-ferrous spring wire with good corrosion resistance and electrical conductivity. Improved strength over phosphor bronze and non-magnetic. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Phosphor Bronze |

ASTM B159 | Cu 94.0 - 96.0%, Sn 4.0 - 6.0% | 0.32 | 105 - 145 | 15 | 6.25 | 200 °F | Non-ferrous spring wire with good corrosion resistance and electrical conductivity. Non-magnetic. |

Nickel Alloys

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 106) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Hastelloy (C276) |

ASTM B574 | Ni 51.0 - 63.5%, Cr 14.5 - 16.5%, Mo 15.0 - 17.0%, Fe 4.0 - 7.0% | 0.32 | 100 - 200 | 30.7 | 11.8 | 700 °F | Good corrosion resistance in chemical process environments. Known for excellent resistance to sulfur and chloride compounds. Useful in marine and waste treatment industries. |

NiSpan C |

AMS 5225 | Fe 45.0 - 51.0%, Ni 41.0 - 43.5%, Cr 4.9 - 5.75%, Ti 2.25 - 2.75%, Al 0.3 - 0.8% | 0.29 | 150 - 190 | 24.0 - 29.0 | 9.0 - 10.0 | 150 °F | Special alloy that is heat-treatable to have a constant modulus over a range of operating temperatures. Material is not stainless and is magnetic. Typically used in timing devices, weighing and geophysical instruments. |

Elgiloy |

AMS 5833 | Co 39.0 - 41.0%, Ni 15.0 - 16.0, Cr 19.0 - 21.0%, Fe 15.0 - 18.0% | 0.30 | 270 - 300 | 32 | 12 | 850 °F | Cobalt-Nickel alloy known for strength and non-magnetic qualities. Excellent corrosion resistance, good for acetic acid, ammonium chloride, citric acid, sodium chloride and sodium sulfite. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Inconel X750 |

AMS 5698 / 5699 | Ni 70.0 min%, Cr 14.0 - 17.0%, Fe 5.0 - 9.0% | 0.30 | No. 1 Temper: 155 Min, Spring Temper: 180 - 220 | 31 | 12 | 750 - 1100 °F | Better strength over Inconel 600. Material is precipitation hardened after spring fabrication to achieve desired properties. No. 1 Temper provides better heat resistance. |

Inconel 718 |

ASTM B637 | Ni 50.0 - 55.0%, Cr 17.0 - 21.0%, Fe 11.0 - 24.0% | 0.30 | 210 - 250 | 29 | 11.2 | 1100 °F | Better strength and heat resistance over Inconel 600. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Inconel 600 |

ASTM B166 | Ni 72.0 min%, Cr 14.0 - 17.0%, Fe 6.0 - 10.0% | 0.31 | 140 - 185 | 31 | 11 | 700 °F | Good corrosion resistance and mechanical properties at moderately elevated temperatures. Also good for cryogenic applications. Used in chemical processing, heat-treating, and aerospace industries. |

Plastic Composite

| Material | Notes | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|

Ultem |

A thermoplastic polyetherimide (PEI) resin and a trademark of SABIC Innovative Plastics IP BV. Ultem is naturally amber colored. Lee Spring uses custom resin blends of six color-coded strengths. | 340 °F | Excellent chemical resistance and thermal properties. Non-magnetic with very low flammability. |

.png)

Sign Up/Log In

Sign Up/Log In